Anti-static aluminum foil bags are widely used in the field of electronics, medical, precision instruments and other packaging materials. In order to ensure the quality of the product and anti-static performance, its production process needs to go through a number of links. We take you to explore the specific process:

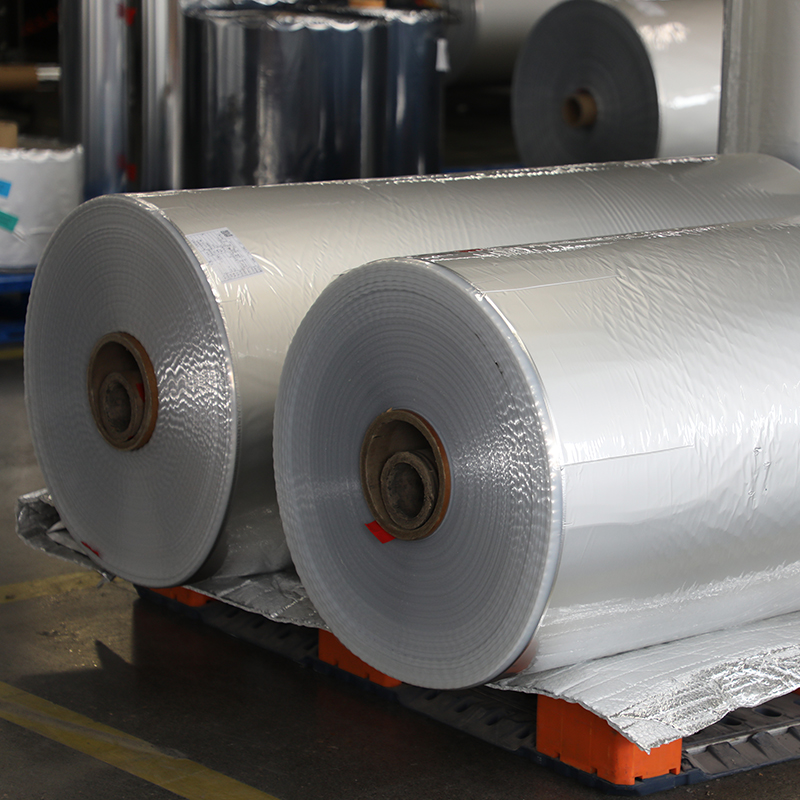

1. Raw material preparation:

The main material of aluminum foil bag is PET/AL/PE, which needs to be used after procurement, quality inspection and other links.

2. Composite:

Aluminum foil bags generally use a three-layer composite structure: the outer layer is PET (polyester resin), the middle layer is AL (aluminum), and the inner layer is PE (polyethylene). Composite is a composite method of gluing three layers of PET/AL/PE material.

3. Curing:

Also known as curing, the composite film into the drying room (curing room). By means of high temperature or ultraviolet irradiation, the glue is cured quickly to improve the fastness of the composite film.

4. Coating:

Coating is the anti-static liquid or conductive liquid evenly coated on the product, which can make the entire aluminum foil bag with anti-static effect.

5. Slitting:

According to the requirements of different sizes, the bag is cut, and the automatic slitter is used to ensure the slitter accuracy and speed.

6. Printing:

The customized text, pattern, etc. can be printed on the bag, according to customer needs to choose the inside printing or table printing, the inside printing is not easy to fall off.

7. Bag making:

The printed bag is folded, sealed and other processing, and finally made into aluminum foil bag.

8. Packing:

When packing, the aluminum foil bag is uniformly checked to ensure that the quality meets the requirements, including appearance, size, sealing and so on. Finally, the qualified aluminum foil bags will be uniformly packed into the box and loaded into the car and shipped.

Only after the above strict production process, can we produce good quality anti-static aluminum foil bags. At the time of purchase, it is recommended to choose manufacturers with qualification certificates and good reputation to ensure product quality and after-sales service.